Consult with us from the planning stage of new development!Overseas transactions amount to over 50%.We can offer direct sales to overseas customers.

Total support for complex electronic parts machining to keep pace with the evolution of today’s most advanced IoT devices!

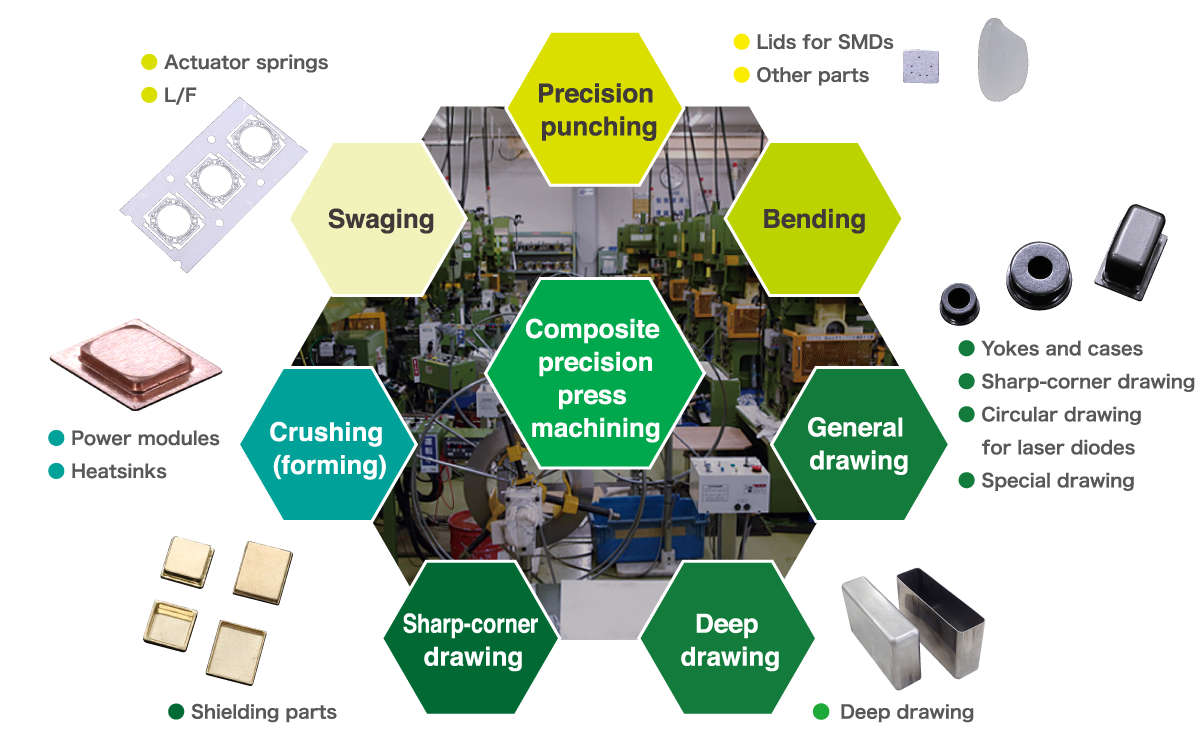

Our complex machining technology for punching, bending, drawing, crushing, and swaging

allows us to perfectly meet the advanced specifications required by our customers.

We give shape to high-level requests not only through individual machining technologies but

by combining them into composite precision press machining. We offer customers the full

package with everything from press machining to washing, metal-plating, and inspection.

We accommodate our customers’ needs not with one single technology but through

all kinds of machining technologies, including precision punching, bending, drawing,

crushing, and swaging.

We also offer high-productivity manufacturing using a super-high-speed press that

operates at up to 1,600 spm.

Press machining always produces burrs. We have our own machining equipment and

can remove burrs at the customer’s request. This process can handle board

thicknesses of 0.03 to 3.3t.

Additionally, we can machine almost any material, including copper and nickel alloys

and stainless steel.

We can handle specifications not only for burr removal but also for heavy cutting,

medium cutting, light cutting, and more.

Unlike most press-based manufacturers, we have our own metal-plating line

(specifically for lids).

We have extensive knowledge about surface treatment techniques from our many

years of experience.

Board thickness: 0.05-0.2t Size: 1.0 x 0.8–19 x 6.5 Materials: Fe-Ni-Co alloys, 42 alloys Plating specifications: electro Ni, electro-less Ni

We do tape-and-reel packaging and tube packaging inside our class 10,000 cleanroom.

・High-speed tape-and-reel packaging machines ・Image recognition pickup-type tape-and-reel packaging machines ・Pickup-type tape-and-reel packaging machines ・Tube packaging machines

We do a lot of business with automobile-related manufacturers, and we strive to

continually improve the quality of our products, particularly where dust is concerned.

We have a cleanroom at our company where we conduct appearance inspection and

measuring tasks in a low-dust environment.

Some of our product appearance inspection operations are handled through

automation.

Automated lid appearance inspection equipment

Automated lid appearance inspection equipment

Leave everything to us,

from precision press machining to surface processing,

packaging, and appearance inspections!

We can handle not only precision press machining but also barrel finishing, washing (single unit /

line), metal-plating (electro Ni / electro-less Ni), packaging (tape-and-reel / tube / bulk packing),

and appearance inspection (visual / fully automatic).

This gives us a major advantage in terms of both quality control and production costs.

We are fully equipped with automatic measurement systems, including image dimension measurement systems and a 3D measurement system. Tape-and-reel packaging and measuring are carried out in our cleanroom (class 10,000).